General Kinematics UN-COALER® Activator/ Feeder is known the world over through many different applications. The state of the art design activates material piles to create a greater yield and has fewer bridging issues than other activators through its vibratory design.

The UN-COALER® Activator/ Feeder utilizes flow control characteristics of a totally enclosed vibrating feeder combined with bin activation to produce amazing results

Recent applications for the GK UN-COALER® Activator/ Feeder have been: potash, pellets, sand, limestone, wood chips, and more. The flexibility of the UN-COALER® has made this unit a hit in a variety of industries and use cases.

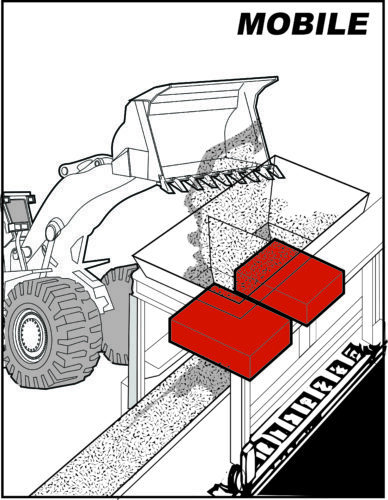

The units are implemented in a multitude of ways from the bottom of a silo to barns to hoppers and now a mobile installation. The UN-COALER® Activator/ Feeder has one extremely unique method of use that has caught the attention of many in the aggregate industry.

In this use case, the mobile UN-COALER® Activator/ Feeder replaces a more costly bucket reclaimer. The Mobile UN-COALER® Activator/ Feeder is rail-mounted and situated under a mobile loader which scoops the material into the tandem units as they all move along a stationary conveyor to produce even feed rates and belt loading. This system has been found to produce better results with a lower equipment investment.

The Mobile UN-COALER® Activator/ Feeder is just one example of the flexibility of design and process that GK equipment is known for the world over. If you have a unique process and are in need of a creative, expertly engineered solution call GK today!