When many people think about “vibratory equipment”, their expectations are that the machine will be loud. In fact, one of the most frequent remarks we hear from customers visiting the GK production facility is how quiet the machines are. Our Vibratory conveyors and process equipment typically vibrate at between 5 Hz and 15 Hz while the range of human hearing doesn’t start until approximately 20 Hz. Although humans cannot hear at these lower frequencies, it is possible to feel the vibrations of the floor and to sense air pulsations near some vibratory equipment.

In addition, some of the materials passing through vibratory equipment, such as heavy metal castings or similar parts, can be quite noisy themselves as they strike the conveying surface and neighboring parts. There are several steps that can be taken to reduce ambient noise levels in these cases, such as the use of sound dampening materials, sound curtains, and sound enclosures. There are also special types of vibratory equipment including flat-stroke and horizontal motion vibratory conveyors which cause very little of this impact-related noise.

Last year GK’s engineering team undertook a study to quantify the decibel levels of different types of vibratory equipment, when running empty, by taking measurements of sound pressure levels at different elevations at a distance of 3 feet from the machines.

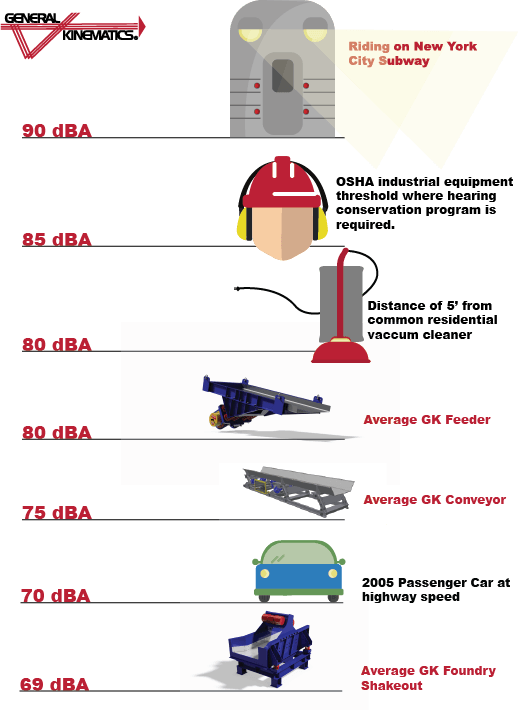

In the United States, OSHA specifies noise level restrictions for equipment that produces sound pressures in excess of 85dBA. Below is a comparison of the noise produced by empty GK equipment to noise in everyday environments.

It is clear GK equipment operates below the threshold for permissible noise levels, but there are ways to make it even better. General Kinematics has conducted laboratory tests and developed a specialized sound dampening Silent-Deck™ technology for use in our vibratory equipment since the early 1980’s. These materials are very useful in lowering the impact sounds which can occur between metal parts striking each other, and when metal parts inside of a vibratory machine vibrate against portions of the vibratory machinery. GK’s current equipment designs include materials that are able to reduce sound pressure levels by as much as 6 dBA in these situations, meaning that a machine utilizing GK’s proprietary sound dampening materials can be as much as 6 dBA quieter than a similar vibratory machine operating at the same speed and vibratory amplitude.

We think this is something to shout (quietly) about. If you are looking for the smartest designed vibratory equipment, give us a call.