We’ve heard it a million times – reduce, reuse, recycle. But really, what’s the point? Doesn’t everything just decompose eventually?

Eventually. Well, I suppose that’s ONE word for it!

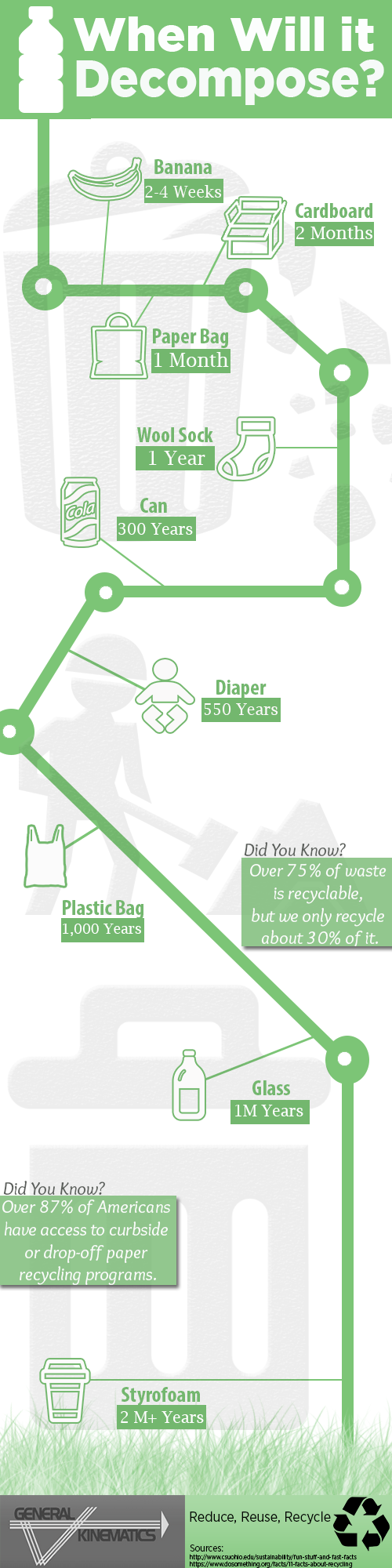

Check out these stats to see how long it takes for common, every day items to decompose.

Share this Image On Your Site

Let’s recap:

- Banana peel: 2-4 weeks (well that’s not so bad)

- Cardboard: 2 months (neither is that!)

- Paper bag: 1 month (hmm … interesting)

- Wool sock: 1 year (I never really thought of a wool sock like that before)

- Aluminum can: 300 years (really?)

- Diaper: 550 years (ummm …)

- Plastic Bag: 1,000 years (yikes)

- Glass: 1 million years (no way!)

- Styrofoam cup: 2+ million years (uh-oh, we’re in trouble)

Well, I guess maybe we should join the party and keep spreading the word about the 3 Rs. If your town doesn’t have a recycling center, it’s time to get one! Contact General Kinematics for help.

Sources:

https://www.dosomething.org/facts/11-facts-about-recycling

http://www.csuohio.edu/sustainability/fun-stuff-and-fast-facts