Waste to Energy is a growing industry around the world. There are so many ways to customize the process and get the most return on your investment. Here at General Kinematics, we know how difficult it can be to find the right equipment for your process.

Let us simplify!

Below you will find some of our most popular waste to energy units and how they can automate your process.

GK Vibratory Transfer Conveyors

Once the waste materials are burned, the ash will need to be transferred. GK Vibratory Transfer Conveyors come in either brute force or balanced machine designs based on material loading conditions and dynamic load transmission to the foundation or structure. These conveyors can be built up to 250 feet in length and have multiple money saving opportunities, including high wear liners that are replaceable to keep your equipment running with minimal maintenance. They are also available with a built-in Grizzly Screen section to avoid a second machine taking up prime real estate.

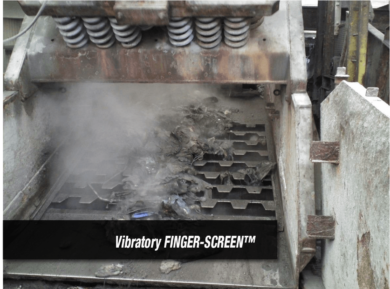

FINGER-SCREEN™ For WTE

Another popular choice for waste to energy plants is the GK Vibratory FINGER-SCREEN™ and Grizzly Screen. This screen separates the bulkies from ash providing optimal material reclamation. Choose a brute force or GK Two-Mass drive to be located either overhead or underhand and get ready to watch these units easily separate the materials, even in up to -6 inch ash!

Vibratory Transfer Feeders

Like the screeners, the GK Vibratory Transfer Feeders are available in brute force or GK Two-Mass designs dependent upon your installation requirements. This popular feeder transfers and meters ash material to your downstream processing line. GK feeders are acclaimed for their durability and reliability, with installations from the 1970’s still running today.

-⅜” Fines Screeners

Looking for finer fines? The GK Vibratory -3/8” Fines Screeners will screen the -⅜” ash material prior to Eddy Current and Ferrous Metal separation. This screen comes with a choice of screen deck design to fit your process with a wire mesh screen cloth or GK Rod Deck. Again available in an Underhand or Overhead GK Two-Mass or Brute force as needed.

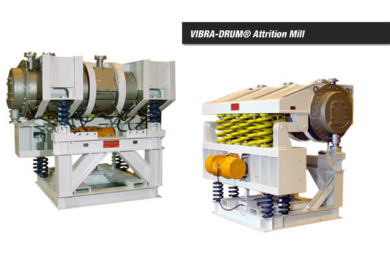

VIBRA-DRUM® Attrition Mill for WTE

Recover metals from bottom ash with the vibratory attrition of VIBRA-DRUM® Attrition for WTE. Our studies show that 93-97% recoveries can be achieved without the use of harsh chemicals. This fully automated system makes it easy to increase your ROI by recovering scrap metals from your waste to energy process.

More Equipment for WTE Facilities

- Main Ash Transfer Conveyors

- Vibratory Scalpers

- Transfer Feeders

- Distribution Conveyors

- Metals Recovery Units

–Finger Screens

–Spreader Feeders

–Picking Conveyors

GK specializes in building vibratory equipment that solves tough process challenges. To learn more about General Kinematics Waste to Energy equipment, contact GK today!