In light of this week’s appearance at the Powder & Bulk Solids show (visit us at Booth 1436) we are doing a roundup of all of GK’s favorite bulk processing conveyors.

General Kinematics has experience creating conveyors for a wide variety of applications, from extreme heat to volatile substances, GK has the solution for every conveying need.

KWIXTROK™ Horizontal Motion Conveyors

This horizontal conveyor is perfect for gently moving materials without the impact of angled conveyors. Great for fragile materials or reducing noise in your facility, this low maintenance unit can also be configured in a myriad of pathways such as a circle, “s” shaped, or rectangle to meet your processing needs.

SPIRA-FLOW™ Vibrating Spiral Elevator

Those of you looking to elevate your product, look no further than the SPIRA-FLOW™ Vibrating Spiral Elevator. Not only can this unique unit lift your material to new heights, but it can also be equipped with direct drying, indirect cooling, and coating to move material up or down based upon your specifications.

SYNCRO-COIL® Vibratory Conveyors

GK’s SYNCRO-COIL® Vibratory Conveyors are built for heavy or medium loads to be able to handle whatever you throw at them. Featuring their SYNCRO-CUSHION™ Coil Spring Drive this unit puts natural frequency to work making it load responsive, meaning it works with your material to improve your process.

Toaster Conveyors

As you may have guessed from the name, these conveyors are ideal for under toasters, dryers, and coolers. As with all GK equipment this unit is expertly engineered to provide even exposure to the temperature element. The perfect low maintenance heat resistant design is built to last.

Vibrating Transfer Conveyors

This light duty unit is the perfect fit for processing free-flowing materials in either food or chemical processing environments. The Vibratory Transfer Conveyor utilizes natural frequency to lower energy consumption while improving your process flow.

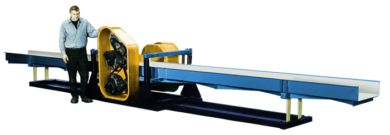

VIBRA-BELT® Vibratory Belt Conveyor

The ultimate fusion of belt and vibratory conveyors to provide you with the best of both worlds. Flexible trough suspension and GK’s proven vibratory drive and reactor systems provide you with a completely different way of conveying. The resulting conveyor can be customized using different materials including stainless steel to provide the desired effect to your process.

Utilizing our extensive engineering background, General Kinematics is capable of providing your process with the perfect conveyor. Our conveyors come in various shapes and sizes and can be covered or open depending on your specifications. To learn more about how GK can provide you with the right conveyor, call GK today and talk to an engineer!